RUBBER MACHINE

- HOME > PRODUCTS > RUBBER MACHINE >

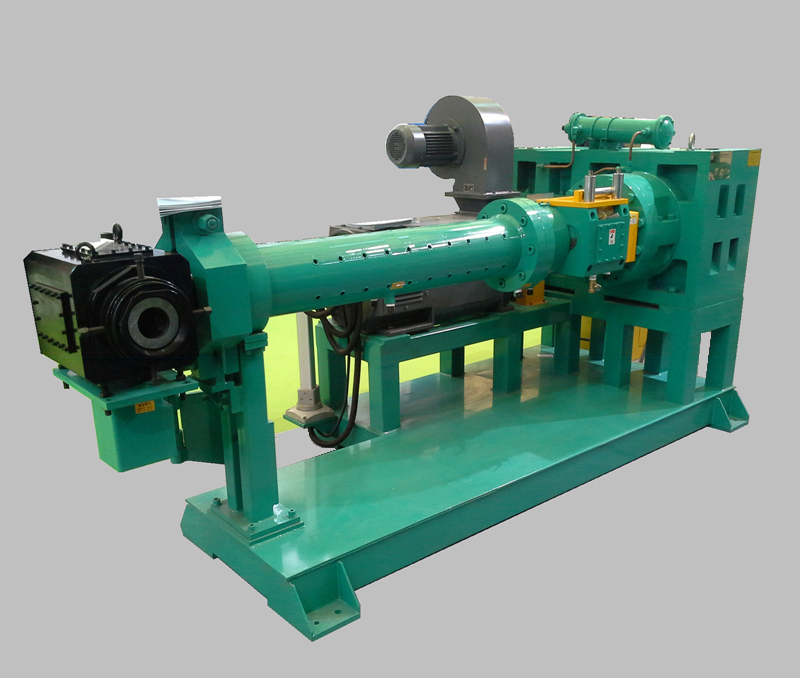

- Product Name:Pin-Barrel Cold Feed Rubber Extruder

- Product Properties:Screw: 38CrMoAlA high quality nitriding steel, quenched and nitrogen treatment; The spiral surface hardness HRC60-65, hard layer depth 0.5-0.7mm; Helical structure in the extrusion and plastication phase with constant depth and variable pitch in different stage; In the feeding stage with 4-wing screw ridge and 2-wing groove. This spiral form has the advantage of high strength, high feeding capacity, shear mixing sufficiently, stable extrusion pressure, good adaptability for all kinds of rubber materials.

- Product Application:Pin-barrel cold feed rubber extruder is mainly used for extrusion of various of rubber pipe, tread,cable and others.

- Description:Main Structure: Screw, Barrel, Reducer

- Views:

- Browse similar products RUBBER MACHINE

I. NAME:

Pin-barrel cold feed rubber extruder

II. FEATURES:

1. Front Barrel: Outer barrel is made of high quality carbon steel; Inner bushing adopts 38CrMoAlA high quality nitriding steel, quenched and nitrogen treatment, surface hardness HRC65-70, hard layer depth 0.5-0.7mm; Bushing outer diameter of the ring is formed with an annular groove for heating and cooling.

2. Screw: 38CrMoAlA high quality nitriding steel, quenched and nitrogen treatment; The spiral surface hardness HRC60-65, hard layer depth 0.5-0.7mm; Helical structure in the extrusion and plastication phase with constant depth and variable pitch in different stage; In the feeding stage with 4-wing screw ridge and 2-wing groove. This spiral form has the advantage of high strength, high feeding capacity, shear mixing sufficiently, stable extrusion pressure, good adaptability for all kinds of rubber materials.

3. Feeding device: Consist of feed rolls, roll covers, bearing blocks, gear pairs, bearings, scraping knives and so on. Special design structure can effectively prevent the material into the feed roller support bearings, to ensure the proper running of the feeding apparatus. Feed roller surface and anti-rubber groove are quenching treatment, with surface hardness HRC40-45 and hardness layer depth 1-2mm. Gear pairs have a separate lubrication system. Feeding device is mounted at the side of the machine body.

4. Feed zone barrel: Involves body, front bushing and rear bushing. The bushing is made of 38CrMoAlA high quality nitriding steel, quenched and nitrogen treatment, surface hardness HRC65-70, hard layer depth 0.5-0.7mm. Body material adopts ZG270-500, forged with cavity for heating and cooling system.

5. Reducer: Equipped with extruding machine special use level 2 reducer, hardened tooth surface gear. Gear pairs are immersed in the lubricating oil to ensure adequate lubrication of the gear pair. Gear shafts and gears adopt two different high-quality high-strength low-carbon alloy steel, gear tooth surface treated by carburizing and grinding, gear engagement precision Class 6. Reducer adopts forced lubrication system.

6. Driving motor: Z4 Series DC motor, the steady-state precision less than 0.1%, with constant torque characteristics, equipped with motor speed measurement device and thermal resistor.

7. DC speed control device: British (EURO) company DC governor, other components adopt domestic high-quality products. Master control cabinet equipped with cooling fans.

8. Three-channel temperature control device: Each channel is an independent control unit. Temperature controller adopts softened water as the circulating medium, with entering water pressure 0.2-0.3Mpa, heating power 9kw per channel and temperature control accuracy±2ºC. Adopt Germany (WILO) company hot water circulation pump, Japan RKC intelligent automatic adjustment temperature controller. Automatic protection function includes automatic water replenishment, hot water circulation pump can not start and heater will not heat at dry state or no water state, over-temperature alarm and automatic power-off, auto-exhaustion and so on.

9. Extrusion head: Cross-shaped or manufactured according to the customers’ specifications.

III. Technical Parameter:

:

Model | XJD-45 | XJD-60 | XJD-75 | XJD-90 | XJD-120 | XJD-150 | XJD-200 | XJD-250 | |

Screw diameter (mm) | 45 | 60 | 75 | 90 | 120 | 150 | 200 | 250 | |

L/D ratio | 8-12 | 8-12 | 8-14 | 12-16 | 12-16 | 12-18 | 12-18 | 12-18 | |

Screw RPM (r/min) | ~70 | ~80 | 60 | ~60 (55) | ~50 | ~45 | ~33 | ~26 | |

Production capacity(kg/h) | 15-25 | 80~150 | 100-180 | 250~350 | 600~800 | 1000-1500 | 1600-2500 | 2800-3500 | |

Main motor power(KW) | 12~22 | 18.5~22 | 37-45 | 45~75 | 75~110 | 160~250 | 220~355 | 355~450 | |

Overall dimension | L | 2165 | 2200 | 2300 | 3360 | 3750 | 5200 | 7150 | ~8,500 |

W | 1100 | 1310 | 1150 | 1150 | 1600 | 1650 | 1950 | ~2,450 | |

H | 1600 | 1400 | 1600 | 1450 | 1550 | 1600 | 2300 | ~2,600 | |

Total weight (kg) | 1200 | 1800 | 2100 | 3000 | 4200 | 5350 | 9800 | ~15,000 | |

- Product Name:Cold Feed Rubber Extruder

- Product Properties:

- Product Application:

- Description:Cold Feed Rubber Extruder

- Browse similar products RUBBER MACHINE